Liaoning Tuohe Technology Co., LTD

-

Manager Li: +86-13582235766 / +86-15720072626

E-mail: sales@lntuohe.cnAdd: Dayou Economic Development Zone, Jinzhou City, Liaoning Province

Quote Now

Solutions for Your Industry, Ready for Your Choice

Special Copper Oxide for Magnetic Materials

In the production process of magnetic materials, the addition of copper oxide is mainly to reduce the sintering temperature of magnetic materials, improve the surface flatness of the product, and the color is black and bright.

Subcategory:

keyword:

Copper oxide

隐藏域元素占位

- Description

-

- Commodity ID: 996361689718677504

Special Copper Oxide for Magnetic Materials

In the production of magnetic materials, copper oxide is added.The main purpose is to reduce the sintering temperature of magnetic materials, improve the surface flatness of the product, and the color is black and bright. The production process is mixed.--pre-sintering--Granulation--Press forming--Slot or Hole--Firing--Precision grinding machine molding and other processes can finally make the finished product, so in any link problems can not do the product.

For the raw material copper oxide, it is necessary to do the corresponding quality control for the production process of magnetic materials, respectively, as follows:

- Mixing: In the production process of magnetic materials, mixing is the first link, so it is necessary to consider how to improve the fineness and fluidity of copper oxide particles, so as to better mix evenly with other raw materials. For this link, our factory Hired relevant industry experts to develop corresponding products, reducing mixing time and improving production efficiency.

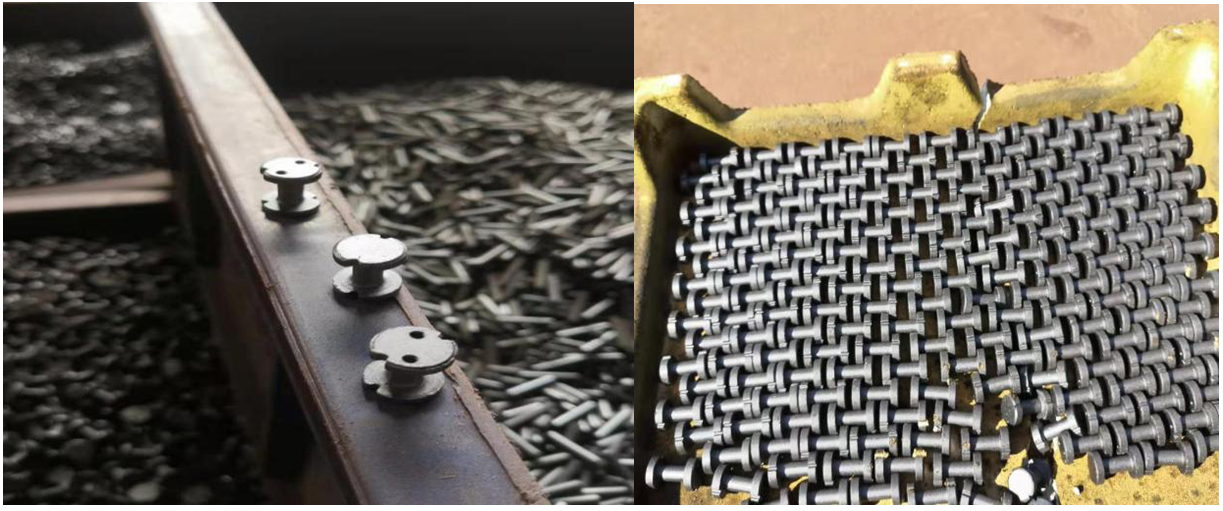

Picture of customer with special copper oxide mixture

Picture of customer with special copper oxide mixture - Pre-sintering and firing: For the pre-sintering and firing process,without affecting the magnetic materialQvalue, inductance (permeability), superimposed current and other indicators,I plant throughChange the crystal structure of copper oxide to reduce the sintering temperature.200thus reducing sintering costs and improving efficiency.

Customer fired good magnetic material

Customer fired good magnetic material

Related products

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!